| Airport Cable | |||

2491X to BS 6004 Cables

2491X to BS 6004 Cables

450/750V PVC Insulated, PVC Sheathed, Screened Controlling Cables (2 core)

RE-Y(St)Y (CU/PVC/OS/PVC 450/750V Class 5)

APPLICATION

The Airprot cables unarmoured versions (Part 2 Type 1) are generally use for indoor installation and suitable for

wet and damp areas. Generally used within industrial process manufacturing plants for communication, data and

voice transmission signals and services, Also used for the interconnection of electrical equipment and

instruments, typically in chemical or petrolchemical industry.

STANDARDS

Basic design to BS 5308 Part 2 Type 1

FIRE PERFORMANCE

| FlameRetardance (SingleVerticalWireTest)** | EN60332-1-2; IEC60332-1-2; BSEN 60332-1-2; VDE0482-332-1; NBN C30-004 (cat.F1);NF C32-070-2.1(C2); CEI 20-35/1-2; EN 50265-2-1*; DIN VDE 0482-265-2-1* |

|---|---|

| Reduced FirePropagation(Vertically-mountedbundledwires &cabletest)** | EN60332-3-24 (cat.C); IEC60332-3-24;BSEN60332-3-24;VDE0482-332-3;NBN C30-004 (cat.F2);NF C32-070-2.2(C1);CEI 20-22/3-4; EN 50266-2-4*; DIN VDE 0482-266-2-4 |

Note:

Asterisk * denotes superseded standard

Asterisk ** denotes that the standard compliance is optional, depending on the oxygen index of the PVC

compound and the cable design.

VOLTAGE RATING

450/750V

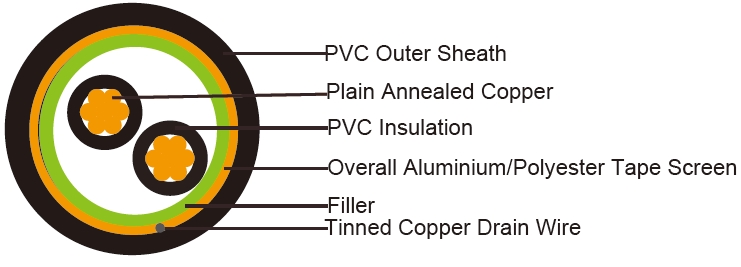

CABLE CONSTRUCTION

Conductor: Plain annealed copper wire, stranded according to BS 6360 Class 5

Insulation: PVC (polyvinyl chloride), type TI1 to BS 6746

Filler, binder: PETP transparent tape

Overall Screen: Aluminium/polyester tape is applied over the laid up pairs metallic side down in contact with

tinned copper drain wire, 0.5mm²

Outer Sheath: PVC Sheath, type TM 1 or type 6 to BS 6746

COLOUR CODE

Insulation Colour as per BS 7671

Black with Arabic numbers printing in white colour

Outer sheath: Black or as order

Physical AND THERMAL PROPERTIES

Operating Temperature: -40˚C up to + 70˚C( fixed installation)

0˚C to +50˚C(during operation )

Minimum Bending Radius: 5 x Overall Diameter

Insulation Resistance Min.: 25 Mohm/km

CONSTRUCTION PARAMETERS

| Conductor | RE-Y(St)Y | ||||||

|---|---|---|---|---|---|---|---|

| No.of CoreXCross Section |

No./ Nominal Diameterof Strands |

Conductor Diameter |

Nominal Insulation Thickness |

Nominal Aluminium TapeScreen Thickness |

Nominal Sheath Thickness |

Nominal Overall Diameter |

Approx. Weight |

| Noxmm2 | No./mm | mm | mm | mm | mm | mm | kg/km |

| 2x1.5 | 30/0.25 | 1.6 | 0.7 | 0.05 | 0.9 | 8.4 | 117 |

Electrical PROPERTIES

Operating Temperature: -40˚C up to + 70˚C( fixed installation)

0˚C to +50˚C(during operation )

Minimum Bending Radius: 5 x Overall Diameter

Insulation Resistance Min.: 25 Mohm/km

Current-Carrying Capacities (Amp)

Conductor |

Reference insulatingwalletc) |

Reference trunkingetc) |

Reference |

Reference |

Reference |

||

Horizontalflat spaced |

Verticalflat spaced |

Trefoil |

|||||

2cables, single- phase |

3 or 4cables, 3-phasea.c. |

2 |

3 or 4cables, 3-phasea.c. |

2cables, single- phase |

3 or 4cables, 3-phase |

2cables,single- phase |

3 or 4cables, |

2cables, single- phase a.c.ord.c.or 3cables |

2 |

3cables, trefoil |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

mm2 |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

1.5 |

18 |

17 |

22 |

19 |

25 |

23 |

- |

- |

- |

- |

- |

Voltage Drop (Per Amp Per Meter)

| Nominal Cross Section Area |

2cables d.c. | 2cables, single-phasea.c. |

3or 4cables,3-phase a.c. | |||

|---|---|---|---|---|---|---|

| Ref.Methods 3and 4 (enclosed in conduitetc, inoron a wall) |

Ref. Methods1 and11 (clipped director ontray stouching) |

Ref.Methods3 and 4 (enclosed inconduitetc, inoron a wall) |

Ref.Methods1, | Ref.Methods1and11 | ||

| 11 and12 (intrefoil) | (Flat and touching) | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| mm2 | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m | mV/A/m |

| 1.5 | 31 | 31 | 27 | 27 | 27 | 27 |